|

|

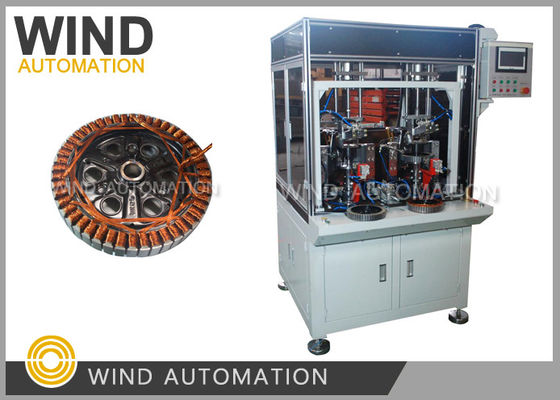

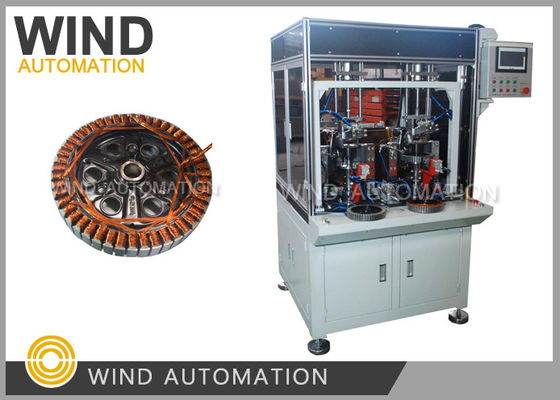

Hub Motor Winding Machine Electric Bicycle BLDC Engine E-Bike Muti Coils Winder

|

Product Details:

Payment & Shipping Terms:

|

| Condition: | New | Certificate: | Main Parts CE |

|---|---|---|---|

| Working Station: | Single Station | Motor Application: | In Wheel Motor |

| Automation Type: | Fully Automatic Winding, Arraying, Cutting | Machine Color: | White Or Per Customer Requirement |

| After Sales: | Ngineers Available To Service Machinery Overseas | ||

| Highlight: | BLDC hub motor winding machine,electric bicycle stator winder,multi-coil e-bike motor winder |

||

Hub Motor Winding Machine Electric Bicycle BLDC Engine E-Bike Muti Coils Winder WIND-HMW-1M

Application:

Electric bike, hub motor, wheel motor, outrunner motor, BLDC Engine outside stator parallel wires winding

Advantages:

1. Hub motor winding passing rate 98% to 99%, means in hub motor production, only 1pc or 2pcs is allowed to fail

2. Self develop mechanical tensioner, one tension can handle serveral wires

3. The operator staff should be familar with operation and commissioing, have good sense of machinery,

Technical Data:

Stator OD : 198mm, 207mm, 226mm,254mm,262mm

Stator Thick : 30 & 35mm Min. 14mm, Max. 35mm

SWG : 24 SWG , 0.56mm ( 0.3mm- 0.6mm )

No of Turns / coil : 4 ~ 8

No of slot : No requirement , normally 48slots to 54 slots

No of parallel wire : 13 to 16

Cycle time : about 5 minnutes Max / pc

Insulation paper's thickness is 0.18~0.20mm

Air Source Pressure:0.4-0.7MPa

Power Supply Voltage:3 phases 380V±10% 50Hz

Power :about 3KW

Change Over time : 10 min Max including hardware and software

Winding Way:

Main Configuration:

|

Control system |

China PLC

|

|

Servo system |

Japan Mitsubish servo system

|

|

Tension system |

Constant torque servo motor, constant tension

|

Please click below picture to view video

Contact Person: Ms. Emily

-

Electric Motor Prototypes 500W Fiber Laser Cutting Machine Before Stacking

-

Inner Winder Stator Winding Machine 1 Minute / PC Automatic BLDC Motor Stator

-

Needle Winding Ceiling Fan Motor Winding Machine For Production Prototypes Stators

-

Double Station Stator Winding Machine For Out Runner Single Phase 3 Phase Fan Motor

-

Motor Winding Machine Motorcycle Digitial Generator Stator Outrunner Segmented Outside Rotor Winder

-

Outrunner Stator Winding Machine Fan Motor Ventilator External Rotor Winder