|

|

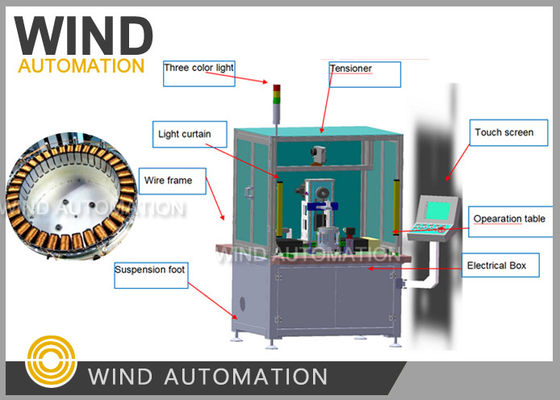

Fully Automatic Motor Winding Machine 8kw Teeth Winding For Coated Stator Stack

|

Product Details:

Payment & Shipping Terms:

|

| Condition: | New | Axis: | 4 Axis |

|---|---|---|---|

| Working Station: | One Station/ Double Station | Winding Speed: | Max. 400RPM According Wire Gauge,Stator Size |

| Automatic Type: | Fully Automatic | Machine Color Motor Winding: | White Or Per Customer Requirement |

| Motor Winding: | Teeth Winding For Coated Stator Stack Or Plastic Caps | After Sales: | Engineers Available To Service Machinery Overseas |

| Highlight: | flyer winding machine,motor winding machine |

||

Stator Winding Machine To Make Coils On Teeth Electrostatic Coating Of The Slots WIND-BLDC

Stator Teeth Winding Machine Application:

Make coils on teeth for inslot stator such as 36 slots stator,

Stator Winding Machine Parameter:

| Model | WIND-BLDC-2,4 |

| Winding Stack | Inslot stator |

| Station | Single station |

| Wire diameter | 0.1-1.2mm( according to stator slot filling rate and slot width) |

| Stator Size | Outer diameter: Max 230mm (9.055'') Inside diameter:Min.10mm (0.394'') Stack weight:Max 10KG (lbs) Stack length:Max 100mm (3.94‘’) |

| Program setting |

The maximum step is 200 steps. The system program stores 10 sets, which is larger than the storage can be uploaded by the computer and downloaded with unlimited storage.

|

| Winding speed | Max.400rpm(according to wire size,stack length and stator size) |

| Axis | 4 axis |

| Total Power | 8KW |

| Input | AC380V ±10%3 phase 50/60Hz |

| Air source | 0.4~0.7Mpa |

| Machine size | About 1000(W)×800(D)×1800(H)mm |

Question and Answer:

1. What is the winding cycle time of below brushless motors?

Cycle time: For winding each stator mentioned above it cost 10 minutes per piece

2. Do we need to use electrostatic coating of the slots in order to use your machine?

![]()

Below samples and drawing are needed for machine manufacturing and commissioning:

1. CAD drawing of stator lamination for checking slot filling rate

2. Winding diagram

3. Copper wire 1 roll enough for winding 2pcs stators

4. Does the stator have positioning slotting place

Main Parts

| No. | Name | Brand | Remark |

| 1 | PLC | YASKAWA | |

| 2 | Servo Motor | YASKAWA | |

| 3 | Touch screen | Weinview | |

| 4 | Sensor | OMRON | |

| 5 | Electric units | Schneider | |

| 6 | Pneumatic units | Xinchen | |

| 7 | Ball bearing | NSK | |

| 8 | Screw guide | HIWIN | |

| 9 | Timing belt | Gates | |

| 10 | Power supply | Mean Well | |

| 11 | Tensioner | ETA-1000/L-R | |

| 12 | Reducer | Nidec-SHIMPO | Heave stator need motor reducer |

Please click below picture to view video of 36slots stator winding machine

This needle winding machine with four axis servo device can winding, indexing, put the wire, demolding automatically, The standard type is flexiable to change tooling for BLDC stator with OD below 120mm (4.72''), ID 10mm (0.39'')to 100mm(3.94''), height 100mm(3.94''), Max stator stack weight:3KGS ( 6.6 lbs)

Contact Person: Ms. Emily

-

Electric Motor Prototypes 500W Fiber Laser Cutting Machine Before Stacking

-

Inner Winder Stator Winding Machine 1 Minute / PC Automatic BLDC Motor Stator

-

Needle Winding Ceiling Fan Motor Winding Machine For Production Prototypes Stators

-

Double Station Stator Winding Machine For Out Runner Single Phase 3 Phase Fan Motor

-

Motor Winding Machine Motorcycle Digitial Generator Stator Outrunner Segmented Outside Rotor Winder

-

Outrunner Stator Winding Machine Fan Motor Ventilator External Rotor Winder