|

|

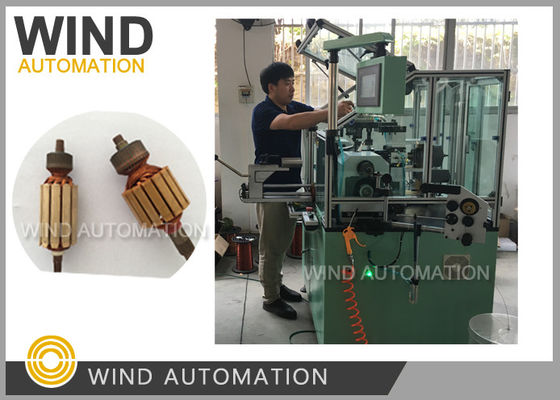

Commutator Armature Dual Flyer Winding Machine / Automatic Coil Winding Machine

|

Product Details:

Payment & Shipping Terms:

|

| Wire Size Handled: | Usually 0.20~1.2mm (AWG17 ~ AWG32) | Max Wire Handled: | 1.35mm (about AWG16) |

|---|---|---|---|

| Winder Flyer: | Double Double Flyer Lap Winding Machine | Armature Manufacturing: | Vacuum Cleaner Hammers Power Tool Armatures |

| Armature Rotor Stack: | Straight Stack Or Skew With Different Initial Positioning Way | Operation Method: | Step, Auto, JOG |

| Highlight: | armature coil winding machine,rotor winding machine |

||

No Hook Commutator Armature Dual Flyer Winding Winder

For Vacuum Cleaners Hammers Power Tool Motor WIND-ST-TD2B

Winder Main Data and Application :

Armature winder for slotted type commutator armature,Vacuum cleaners hammers power tool

in which the commutator is without hook tang and have a special way for pressing and hooking

the copper wire to commutator wire slot area

| Armature Informaiton | Size | Remark |

| Copper Wire Diameter | 0.20~1.2mm | AWG17 ~ AWG32 |

| Armature Diameter Range | 20~90mm | 0.787'' ~ 3.543'' |

| Armature Stack Length | 10~130mm | 0.394'' ~ 5.118'' |

| Commutator Diameter | 8~60mm | 0.315''~2.362'' |

| Armature Slot Number | Odd, Even Slots | |

| Turns No. | 0~99999 | |

| Flier Fork Speed | 0~2000RPM | |

| Indexing Speed | 0~2500RPM | |

| Total Power | 3.5KW | |

| Operation Method | Step, Auto, JOG | |

| Power Source | AC380V 50/60Hz | 3Phase |

| Air Source | 5~7KG/cm2 | 0.5~0.7MPa |

| Gross Weight | about 1000KGS | |

| Dimension | 1530mm x 1280 mm x 1650mm |

Armature Winder Main configuration:

PLC: MITSUBISHI

Servo control system: DELTA

Touch screen: MCGS7062KS

Pneumatic system: AIRTAC

Tension :Hysteresis tension

Linear guide way: HIWIN

Main electrical components:Korea and Japan

Armature/Rotor Winder Advantages:

1. Armature winder WIND-ST-TD2B is dedicated machine for winding slotted type

no hook commutator armature,obtain good adaption for slot type commutator with groove

2. No need to work with special designated slotting undercutting machine

3. Comparing to hook type armature, slotted type armature save copper wire and reduce cost,

but winding slotted type armature can be a challenge

because slotted type commutator armature winder is different from hook type armature winder

WIND-ST-TD2B is the best winder for slotted type commutator in China during machine manufacturers

4. 98% yield rate above assured when the slot commutator quality is good

![]()

Armature Winding Machine Operation process:

Operator only need to load and unload armature,

other actions such as hooking, winding, indexing and cutting are automatcial process

Winding and welding are the two most improtant process in building motors, WIND-ST-TD2B winding

machine is mainly for automatical lap winding a slotted type commutator armature as below:

1. Straight stack armature and

2. Skew lamiantion rotor

The purpose of these armature winder is to create a magnetic field lap winding coil

when a current is run through them,

Contact Person: Ms. Emily

-

5Slot Armature Rotor Winding Machine DC Brush Motor Four Station WIND-ODD-1

-

Solar Energy Armature Coil Winding Machine Motor Winder 16 Hook 16 Slot

-

Solar Steering Motor Armature Winding Machine Flyer Winder Rotor Lap Winder

-

Automatic Dynamic Balancing Machine For Small Armature Rotor Adding Weight Type

-

CE Armature Winding Machine Dc Commutator Motor Fully Automatic Production Line

-

Flier Type Armature Winding Machine Fully Automatic 4 Pole Lap Coil Winder