|

|

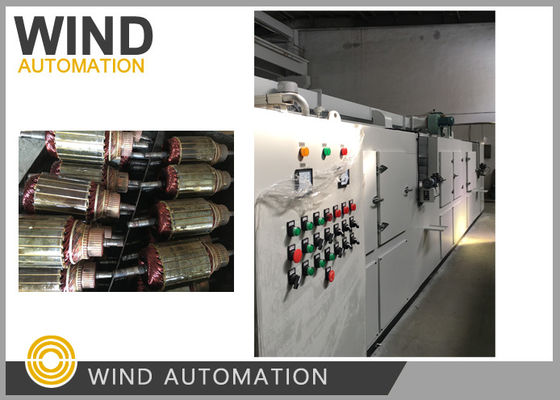

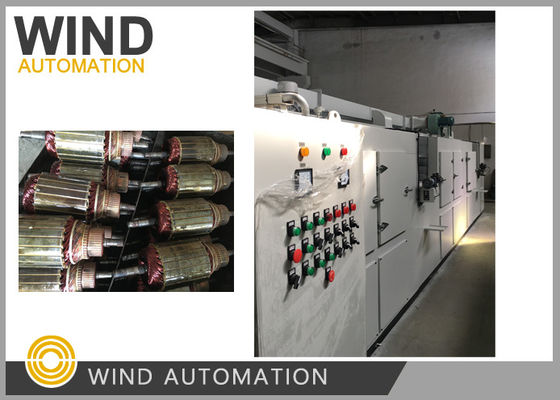

Automatic Armature Roll and Dipping Impregnation Varnish Insulation Machine

|

Product Details:

Payment & Shipping Terms:

|

| Condition: | New | Armature Insulation: | Armature Trickling/ Roll And Dip |

|---|---|---|---|

| Power Consumption: | Customised 26KW For A 127 Station Machine | Machine Length: | 3.8*1.5*2.1M Is Related To Armature Size,curing Time And Output Requirement |

| Power Source: | Electricity Or Customised | After Sales: | Machine Almost No Need Maintenance |

| Highlight: | impregnation line,varnish impregnation machine |

||

Automatic Armature Roll and Dipping Impregnation Varnish Insulation Machine WIND-ZDG

Application and Purpose:

The motor coil must be impregnated with insulating varnish and its adjacent parts,

Let the conductor wire, slot insulation isolation parts whole compacted and immerged with

insulating resin coating become strong overall density.

Competitive Advantages:

1.Fully automatic, operator only need to load and unload armature

2.Rolling and dipping device is at top layer of machine,easy to adjust and maintain

3.Centrifigution exhausting blower suck the exhausting gas,Environment friendly

|

Chiller Needed

|

Usually the varnish dipping machine for stator and

rolling and dipping machine for armature need chiller

|

|

Reson

|

Becasue heated workpiece is in the varnish which transfer heat and rise varnish temperature

|

|

Purpose

|

The chiller will keep the varnish quality, no deterioration and thinner

|

Example of one Armature roll and dip Machine proposal:

The following purpose can be achieved through the insulation treatment:

1. To improve the moisture resistance of motor insulation

Any insulating material is more or less absorbing moisture in moist air. Such as Electrotechnical insulation

material paper DMD,PMP,Polyester, the moisture in the air is easily penetrated into the insulation material

along the capillary, thus the performance of the insulating material decreases significantly. The insulation

treatment will make the surface of the windings and coils form a smooth, pinless film or insulation seal

layer, which will greatly reduce the invasion of moisture and improve the moistureproof performance of the

motor.

2. Improve the heat resistance of motor insulation

Motor insulation materials in an insulating impregnating varnish before the material after heating the

internal decomposition of gas water molecules of low molecular substances, accompanied by oxidation,

changes in material properties such as mechanical strength, moisture resistance, reduce the decline of

brittle materials, have electrical properties such as insulation resistance and breakdown voltage

decreased, this phenomenon known as the aging of insulation materials, insulation insulation contact area

but after the treatment of material and air is greatly reduced, the rate of oxidation is greatly reduced, in

the same service life, the use of the temperature of the motor can be improved. Therefore, the heat

resistance of the motor insulation is improved.

3. Improve the thermal conductivity of the motor

The electrical insulation layer of air gap large, while the thermal conductivity of the air gap is low, the air

gap is filled with dipping paint, varnish and perfusion ratio due to thermal conductivity of air gap, so the

electrical winding motor and a corresponding increase in the conduction of heat, will greatly reduce the

motor temperature rise. The experimental data show that the temperature rise can be reduced by 10-

20%.

4. Improve electrical and mechanical properties of motor insulation

The motor winding coil and the insulation treatment, winding and Core Bond into a solid whole film will void

windings and the notch is full, the insulating layer is formed in a certain thickness of winding end of the

head, there is no gap inside the water is not easy to enter, so the insulation resistance and breakdown

voltage are improved, and at the same time winding core non relative movement, have sufficient strength

to resist the external vibration and stress, and bear the motor assembly process of mechanical impact,

thus avoiding the mechanical action of damage.

The motor windings impregnated after winding insulation system and the core to form a solid whole

reduces the effects of mechanical vibration and electromagnetic force vibration generated by the motor

during operation, the reinforcement effect on the machine, avoid wire between the wire and the core or

tank wall due to vibration, friction and damage the insulation displacement loose structure. The organic

insulation material inside the motor not only improves heat resistance and electrical performance, but also

improves the mechanical strength of the insulation material itself after impregnation. Because the

insulating material is heated, the material will change, releasing gas, water and carbonaceous materials,

lose flexibility, but after impregnation, pyrolysis, under heat hydrolysis process can greatly retard

mechanical flexibility material to maintain long-term, while insulating paint formed by the paint film has

certain elasticity and adhesion in the hot state, the material between the binding force of strengthening,

forming a strong overall, greatly enhance the strength of the system.

5. Improve chemical corrosion resistance

The motor through the impregnation treatment, to prevent all kinds of insulation materials and solvent

around the motor and direct contact with corrosive chemicals, which can improve the stability of chemical

substances of the motor due to the insulating encapsulation, shut off from the world body contact, improve

the winding stability, selecting suitable varnish resin materials can make the winding insulation with anti

mildew, anti oil, anti corona, flame retardant performance.

Parameter:

Working position: 60*2

Position pitch: 152.4mm

Heating time: ≤45 min

Tunnel working temperature: 0 to150 ℃

Pitch time: 0-10min adjustable

Power consumption: 36 KW

Dimension: 6.2*1.15*2.1

Weight:Around 4.2 Ton

Production capability: 700pcs/8 hours

Contact Person: Ms. Emily

-

Peristaltic Pump Trickle Impregnation Machine Impregnation Insulation Tunnel

-

WIND-ZCJ Trickle Impregnation Machine Vacuum Pressure Impregnation

-

Small Frame Stator Varnish Impregnation Machine Dipping Depth Below 300mm

-

Big Frame Stator Varnish Trickle Impregnation Machine Dipping Depth Above 300mm

-

Fully Automatical Trickle Impregnation Machine Stator Heat Treatment Oven Coated With Resin Varnish

-

Automatic Stator Varnish Dipping Machine Motor Impregnation Insulation