|

|

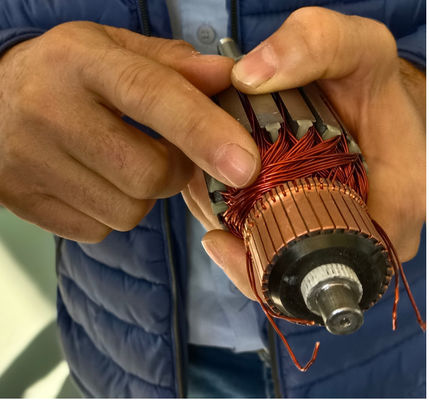

Automatic Armature Winding Machine For Slotted Commutator No Hook Skew Rotor

|

Product Details:

Payment & Shipping Terms:

|

| Armature Commutator Type: | No Hook Commutator,Slotted Type Riser Type Commutator | Armature Manufacturing: | Vacuum Cleaner Hammers Power Tool Armatures |

|---|---|---|---|

| Winder Flyer: | Double Double Flyer Lap Winding Machine | Max Wire Handled: | 1.35mm (about AWG16) |

| Armature Rotor Stack: | Straight Stack Or Skew With Different Initial Positioning Way | Operation Method: | Step, Auto, JOG |

| Highlight: | armature coil winding machine,dynamic balancing machine |

||

Automatic Armature Winder For Slotted Commutator No Hook Skew Rotor WIND-ST-TD2B

Application:

Armature winder for no hook slotted type commutator armature,Vacuum cleaners hammers power tool

Advantages:

1. No need to work with special designated slotting undercutting machine

2. Slotted type armature save copper wire and reduce cost comparing to hook type armature,

but winding slotted type armature can be a challenge,

WIND-ST-TD2B is the best winder for slotted type commutator in Chin among winder manufacturers

4. 98% yield rate above assured based on the commutator quality is good

Fully automatic winding machine filed Japan machine manufacturers are the pioneer, the rising demand

for high quality products and low labor cost, operator only need to ensure enough raw materials, and

replace them in time without workpiece or copper wire, so that continuous production can be ensured.

The number of shaft is usually high, so as to achieve high efficiency production. A machine with enough

automation can meet the requirements of an employee handle two or three winding machines at the same

time.

Suggestion:

1. What is Wire size and Wire slot size(Length,width and depth) data

Wire size 17AWG (1.15 mm), Slot: blade width 1.143, length=7.14 mm,

depth= 5.95 mm

In normal condition,the wire slot should have enough space for the wire to stay inside

and Wind Automation think if the depth is bigger, the wire can acquire more space to stay inside slot,

while depth is more, length is more too

2. Could you please check if the commutator was pressed consistanctly each time at same location

according armature stack?

The push pin witness marks on the commutator are consistent, so commutator slotting is even uniform

Armature commutator and stack position is very important for indexing consistantly

|

Wire Gauge |

Usually 0.20~1.2mm, Max machine handled 1.35mm (about AWG16)

|

|

Commutator type |

Slotted type riser type not hook type commutator

|

|

Automatic or semi |

Automatic,operator only need to load and unload armature, other actions such as

hooking, winding, indexing and cutting are carried out by winding machine

automatically

|

Please click below picture to view video

Contact Person: Ms. Emily

-

5Slot Armature Rotor Winding Machine DC Brush Motor Four Station WIND-ODD-1

-

Solar Energy Armature Coil Winding Machine Motor Winder 16 Hook 16 Slot

-

Solar Steering Motor Armature Winding Machine Flyer Winder Rotor Lap Winder

-

Automatic Dynamic Balancing Machine For Small Armature Rotor Adding Weight Type

-

CE Armature Winding Machine Dc Commutator Motor Fully Automatic Production Line

-

Flier Type Armature Winding Machine Fully Automatic 4 Pole Lap Coil Winder