|

|

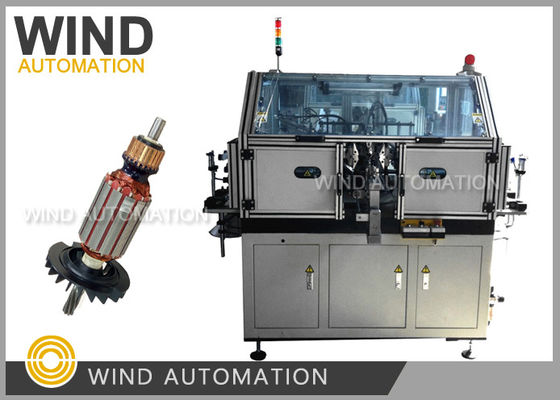

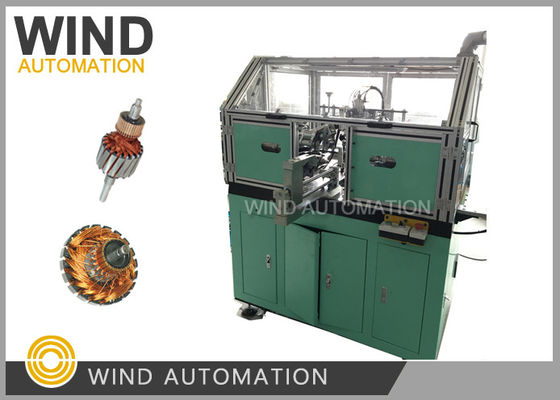

Armature Coil Winding Machine Power Tool Mixer Vacuum Cleaner Motor Winder

|

Product Details:

Payment & Shipping Terms:

|

| Armature Type: | Hook Type | Armature Manufacturing: | Power Tool, Mixer, Vacuum Cleaner, Automoible Oil Pump |

|---|---|---|---|

| Straight Or Skew Armature: | Straight Stack Or Skew With Same Positioning Way | Handled Wire Range: | Usually 0.16~1.2 Mm, Max Wire Machine Handled 1.35mm (about AWG16) |

| Human-Machine Interface: | Diagnose Show On Screen | Operation Method: | Step, Auto, JOG |

| Highlight: | rotor winding machine,dynamic balancing machine |

||

Power Tool Mixer Vacuum Cleaner Motor Armature Coil Winding Machine WIND-STR

Application:

Armature double flyer winding machine WIND-STR takes conductors from two separate reels of wire

simultaneously to wind two slots together. Once would with the correct number of turns and connected to

the respective commutator hook, the armature is indexed automatically to the next pair of slots to be

wound. This WIND-STR armature winder is a fast flyer coil winding machine for motor mass production

manufacturing of hook type commutator armature,Mixer,Vacuum cleaners, Household

applicances,Hammers,Power tool...

Advantages:

1. Easy to changeover and maintenance

2. The winding parameter can be setted on touch screen for armatures

as 12 slots, 24 hook

12 slots, 12 slots

Feature:

|

Lap winding with double flyer wire

gauge range |

Series motor include dc motor wiper, power tools,mixer,blender,

automobile car motor etc

|

|

Armature commutator type |

Hook type

|

|

Automatic or semi automatic |

You only need to load and unload armature, other actions such as

hooking, winding, indexing and cutting are wound by machine

automatcially

|

Parameter Data:

Wire diameter range: 0.16~1.2 mm

Armature diameter: 20~85 mm

Stack length: 10~70 mm

Shaft diameter: 3~15 mm

Shaft length: less than 250mm

Armature Slot: even slot

Turn number: 0~9999

Commutator diameter: 8~40 mm

Winding speed: 0~2500 rpm

Winding motor power: 1.5KWX2

Angle detecting speed: 0~3000 rpm

Angle detecting motor power: 0.75KWX1

Air supply pressure: 4~6 Kg/cm2

The machine total power: 4.0 KW

Voltage: three phase AC 380V 50/60 Hz

Weight: 1250 Kg

Dimension: 2000(length)X1000(width)X1800(height)mm

Package size 1800*1510*1920mm is about 5.2 CBM

HS code: 8479811000

The armatures wound by double flyer winding machine WIND-STR passed the pin hole test of Japanese

based company, please click the link to see the video of winding machine demo for Japanese based

company electric motor armature https://vimeo.com/123798436

An armature generally refers to one of the two principal electrical components of an electromechanical

machine - a motor or generator, but may also mean the pole piece of a permanent magnet or

electromagnet, or the moving iron part of a solenoid or relay.

The other component is the field winding or field magnet. The role of the "field" component is simply to

create a magnetic field for the armature to interact with, so this component can comprise either permanent

magnets, or electromagnets formed by a conducting coil.

The armature, in contrast, must carry current so it is always a conductor or a conductive coil, oriented

normal to both the field and to the direction of motion, torque (rotating machine), or force (linear

machine). The armature's role is two-fold: (a) to carry current crossing the field, thus creating shaft torque

(in a rotating machine) or force (in a linear machine), and (b) to generate an electromotive force ("EMF").

In the armature, an electromotive force ("EMF") is created by the relative motion of the armature and the

field.When the machine is acting as a motor, this EMF opposes the armature current, and the armature

converts electrical power to mechanical torque (and power, unless the machine is stalled) and transfers it

to the load via the shaft. When the machine is acting as a generator, the armature EMF drives the

armature current, and shaft mechanical power is converted to electrical power and transferred to the load.

(In an induction generator, these distinctions are blurred, since the generated power is drawn from the

stator, which would normally be considered the field.)

A growler is used to check the armature for shorts, opens and grounds.

Armature windings are the essential features of electric machines. The field windings are simple

arrangements with concentrated cols(i.e coils in which all the turns have tha same magnetic axis).

Armature windings on the other hand comprise a set of coils embedded in the slots.

Please click below picture to view video

Contact Person: Ms. Emily

-

5Slot Armature Rotor Winding Machine DC Brush Motor Four Station WIND-ODD-1

-

Solar Energy Armature Coil Winding Machine Motor Winder 16 Hook 16 Slot

-

Solar Steering Motor Armature Winding Machine Flyer Winder Rotor Lap Winder

-

Automatic Dynamic Balancing Machine For Small Armature Rotor Adding Weight Type

-

CE Armature Winding Machine Dc Commutator Motor Fully Automatic Production Line

-

Flier Type Armature Winding Machine Fully Automatic 4 Pole Lap Coil Winder