|

|

Slot Liner Stator Insulation Cuffing And Cutting Machine For Roll Width 600mm

|

Product Details:

Payment & Shipping Terms:

|

| Condition: | New | With Or Without Heater: | No Heating |

|---|---|---|---|

| Edge Folded Width: | Edge Bending 3mm~10mm | Cutting Length: | 10 ~ 9999 Mm |

| Machine Color: | White Or Per Customer Requirement | After Sales: | Simple Machine Only Need To Replace Cutter |

| Highlight: | 600mm slot liner stator machine,stator insulation cutting machine,slot insulation cuffing machine |

||

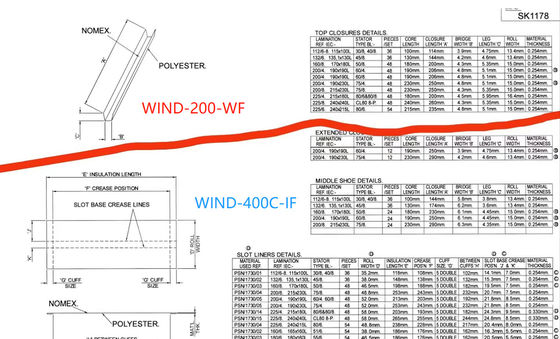

Slot Liner Stator Insulation Cuffing And Cutting Machine For Roll Width 600mm WIND-600C-IF

Slot Liner Stator Cuffing Machine application

This cuffing and cutting machine form the insulation pape for slot liner stator to do manual paper inserting,

The paper roll width can be up to 600mm, also other roll width cuffing machine can be custom made,

Insulation polyester film,DMD,PET,NMN,NHN,Nomex for application such as pump,ceiling fan, compressor,hood motors

The insulaiton materials are mainly used as a slot liner,slot closure,phase and turn-to-turn insulation in

low or medium voltage electrical motors.Besides it is also used as interlayer insulation in transformers and

other electrical appliances.

Electrical Insulation - Wiring, Sleeving & other Electrical Sheilding Products. These products are used in

electrical applications to insulate high voltage current from surrounding areas. These products are

typically known for dielectric strength, arc resistance, thermal performance and insulating properties.

Common applications include dry and oil-filled transformers, switch gears, relays, wire wrap, welding

apparatus, electrical fixtures, commercial & residential electrical, lighting systems and more. These

products are known for their ability to insulate electrical current, withstand mositure and corrosion, and

resist arc and flame. Many of these materials can serve as practical and safe insulators for low to

moderate voltages (hundreds, or even thousands of volts).

Advantages

1. Simple and easy to operate

2. Machine can cut and bend insulation for the motors and

also cutting insulation without bending for other type of slotless motor

3. No maintenance needed, only polish or replace cutter after 2 year to 5 years usage

Parameter

| Paper width: | 50mm~600mm |

| Feeding length: | 10mm-9999mm |

| Fold edge width(Cuff height): | 3~10mm |

| Insulation thickness: | 0.01mm~0.5mm |

| Cycle time: | 1s/pc (accoding to feeding length) |

Paper width, feeding length and fold edge(cuff height) is adjustable

PLC: Mitsubishi

Stepper Motor: China local brand

Sensor: Omron

Other electrical parts: Schneider

Input: 220V/50Hz/60Hz

Weight: ≈ 300kg

Please click below link to view video

Electric motor insulation material cuffing,creasing and cutting machine WIND-600-IF insulation paper forming from EmilyGao of coils winding supply on Vimeo.

Contact Person: Ms. Emily

-

Motor Stator Slot Insulation Machine DMD Paper Inserting BSG New Energy Drive

-

Semi Automatic Commutator Mica Undercutting Machine With Touch Screen

-

WIND-150-IF Slot Insulation Machine Cell Insulation Forming Stator Paper Cuffing Creasing And Cutting

-

DMD Material Paper Inserting Machine 96 Slots New Energy Drive Motor Stator

-

Stator Winding Machine Slot Cell Inserter Indexing Device Servo Motor , Feeding Device Servo Motor

-

150mm Slot Insulation Machine / Insulation Cell Folding And Creasing Machine