|

|

How To Produce BLDC Motor With Winding Machine Wire Broken Alarm

|

Product Details:

Payment & Shipping Terms:

|

| Condition: | New | Certificate: | CE |

|---|---|---|---|

| Working Station: | Single Station | Winding Speed: | 300RPM To 500RPM According Wire Gauge |

| Automatic Type: | Fully Automatic | Machine Color: | White Or Per Customer Requirement |

| Wire Broken: | Alarm | After Sales: | Engineer Available |

| Highlight: | BLDC motor winding machine,winding machine wire broken alarm,needle winding machine for BLDC |

||

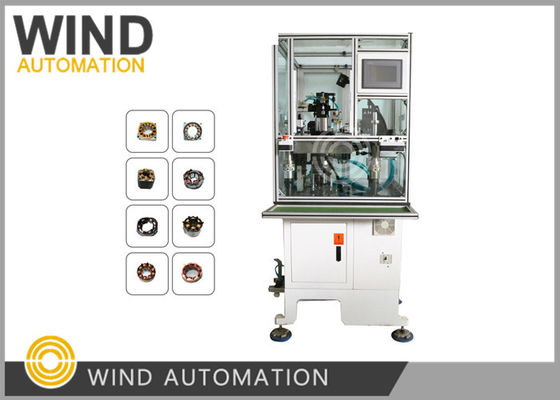

How To Produce BLDC Motor With Winding Machine Wire Broken Alarm WIND-3A-TSM

Application:

Needle winding BLDC stators of Sewing Machine,Air conditioning compressor, Refrigerator

compressor,water pump automotive application , fuel pump motor with 6 poles, 9 poles, 12 poles or

18 poles

Advantages:

|

Fast as three head winding

machine |

3 needles wind 3slots at same time,

wider can finish the winding in3 times for 9poles BLDC stator

|

|

Winding Range |

3 phase BLDC motor with same winding way for each phase,

Especially suitable for thick wire diameter around 0.8mm (AWG20)

|

|

Wire Broken Alarm |

With wire broken alarm device, in the case of wire broken during winding, the operator can easily know and don't have to observe even the situation of wire broken is rarely during winding motor for sewing Machine,air conditioning compressor, refrigerator compressor,water pump automotive application,fuel pump

|

Feature:

Brushless motor stator winding machine WIND-3A-TSM is designed to produce multi poles 3phase stator

Its winding track is in square shape,It does wires winding and arraying at same time and automatically.

The slots needle winding, arraying,indexing,place bridge wire,cut wires are fully automatically.

Parameter:

Wire diameter:0.08~1.2mm (AWG17~AWG39)

Stator ID:15~65mm

Core length:7-110mm

Turns No.0-99999

Operation option: stepping/Auto

Stator poles: 6 poles, 9 poles, 12 poles,18 poles (Customized)

Air pressure:5~7kg/square centi-meter

Power:2KW, AC220V 50/60Hz

Weight: about 450kgs

Dimension: 1600(L)x1100(W)x1400(H)mm

Question and Answer:

1. Which type of stator needle winding shall we select for our stator in attached drawing?

Per your winding data Number of turns 27, wire diameter 0.8mm,

the winding speed we suggest is 300RPM, and it take about 1mintutes to get 1pc wound stator,

In one hour you can get more than 60pcs

3. What's the material list we shall provide for machine trail?

Below samples are needed for machine manufacturing and commissioning:

1. Stator stack 5pcs without winding

2. Wound stator 1pc

3. Copper wire 1 roll enough for winding 15pcs stators

Please click below picture to view video

Contact Person: Ms. Emily

-

How to produce BLDC Motor Straight Lamination Stator Stack with Needle Winding Machine

-

12 Slots Needle Winding Machine BLDC Motor Stator 1.13mm AWG17 Copper Wire

-

BLDC, PMSM and EV Motors Stator Needle Winding Machine For Straight Lamination Stator

-

BLDC Motor Stator Needle Winding Machine 60RPM Parallel Wires To 600RPM Thin Wire

-

BLDC Inner Stator Pole Winding Machins For 2/4/6 Poles With Single Or Multiple Wires

-

Four Nozzles Stator Needle Winding Machine For 4 Poles Shaded BLDC Motor