|

|

How to produce BLDC Motor Straight Lamination Stator Stack with Needle Winding Machine

|

|

Product Details:

Payment & Shipping Terms:

|

| Stator Stack: | Straight Stack Not Skew Stack | Certificate: | CE |

|---|---|---|---|

| Working Station: | Two Or Four | Max Wire: | 1.2mm |

| Automatic Type: | Fully Automatic Can Handle Thin Wire Thick Wire | Condition: | New |

| Machine Color: | White Or Per Customer Requirements | After Sales: | Engineers Available To Service Machinery Overseas |

| Highlight: | needle winder,bldc winding machine |

||

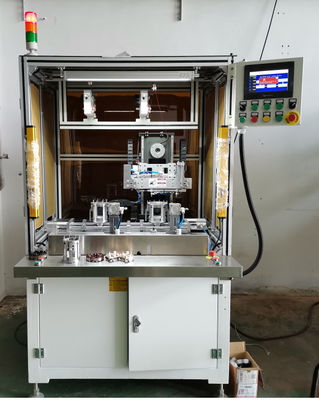

Straight Lamination Stator Needle Winding Machine For BLDC Motor

Needle winding BLDC stators of Sewing Machine,Air conditioning compressor, Power tool,

Refrigerator compressor,water pump automotive application , fuel pump motor

Two station BLDC Stator winding machine WIND-BLDC-2 wind the brushless DC motor stator with two station to improve efficiency, easy to change tooling

Parameter

Wire diameter:0.08 to 1.2mm

Stator OD: 12 to 130 mm

Stack height: 5 to 100mm

Four Axis, Flexible to winding,

Winding motor: Servo motor Yaskawa 3000W 1pc

Indexing motor: Servo motor Yaskawa 3000W 1pc

Wire Arraying motor: Servo motor Yaskawa 400W 2pcs

Speed: 300 to 600 RPM

Air pressure:5~7kg/square centi-meter

Power:AC380V 50/60Hz

Weight: about 1500KGS Dimension: 1100mm*900mm*1600mm

Below samples are needed for machine manufacturing and commissioning:

1. Stator stack 5pcs without winding

2. Wound stator 1pc

3. Copper wire 1 roll enough for winding 15pcs stators

Main Parts

| No. | Name | Brand | Remark |

| 1 | PLC | YASKAWA | CE Label |

| 2 | Servo Motor | YASKAWA | CE Label |

| 3 | Touch screen | Weinview | CE Label |

| 4 | Sensor | OMRON | CE Label |

| 5 | Electric units | Schneider | CE Label |

| 6 | Pneumatic units | Airtac | CE Label |

| 7 | Air pressure sensor | Airtac | CE Label |

| 8 | Ball bearing | NSK | CE Label |

| 9 | Screw guide | HIWIN | CE Label |

| 10 | Synchronous belt | Gates | CE Label |

| 11 | Power supply | Mean Well | CE Label |

| 12 | Tensioner | Zhangli | CE Label |

![]()

Please click below link to watch machine working

Question & Answer

Contact Person: Ms. Emily

-

12 Slots Needle Winding Machine BLDC Motor Stator 1.13mm AWG17 Copper Wire

-

BLDC, PMSM and EV Motors Stator Needle Winding Machine For Straight Lamination Stator

-

BLDC Motor Stator Needle Winding Machine 60RPM Parallel Wires To 600RPM Thin Wire

-

How To Produce BLDC Motor With Winding Machine Wire Broken Alarm

-

BLDC Inner Stator Pole Winding Machins For 2/4/6 Poles With Single Or Multiple Wires

-

Four Nozzles Stator Needle Winding Machine For 4 Poles Shaded BLDC Motor