|

|

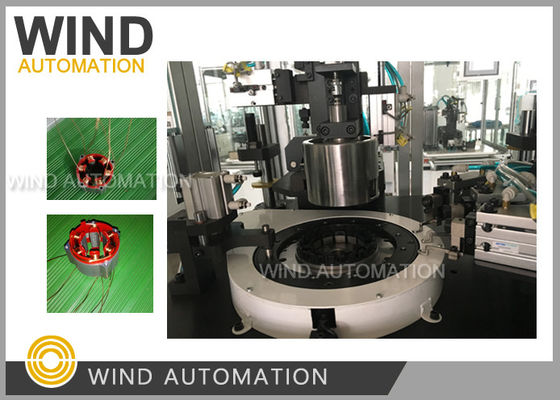

6 Poles BLDC In-Slot Motor Stator Needle Winding Machine Inner Winding

|

Product Details:

Payment & Shipping Terms:

|

| Condition: | New | Certificate: | CE |

|---|---|---|---|

| Working Station: | Single Station | Automation Type: | Fully Automatic |

| Machine Color: | White Or Per Customer Requirement | After Sales: | Engineers Available To Service Machinery Overseas |

| Highlight: | needle winder,bldc winding machine |

||

6Poles BLDC In-Slot Motor Stator Needle Winding Machine Inner Winding WIND-3A-TSM

Application:

6 poles, 9 poles, 12 poles or 18 poles 3Phase Brushless Motor which winding way of three phase ABC

should be same.

Covering Air conditioning compressor, Refrigerator compressor,

Water pump automotive application , Fuel pump motor.

Advantages:

|

Stator during winding |

Stator is stationary during the winding which don't hit the nozzle

|

|

Wire Gauge |

Wide copper wire adaption range from 0.08~1.2mm (AWG17~AWG39)

especially suitable for winding thick wire diameter around 0.8mm (AWG20)

|

|

One station |

Three nozzles winding at same time act as a three station stator winder and

at same time one station stator winder don't have synchronization issue.

|

Feature:

Brushless motor stator winding machine WIND-3-TSM is designed to produce multi poles stator.

Its winding track is in square shape, needle moves only vertically,stators are placed on rotating tool

for indexing,stator is stationary during the winding

Winding machine does wires arraying and winding at same time automatically.

It is the best sold needle winding machine during the stator winders WIND-TSM Series

Parameter:

Wire diameter:0.08~1.2mm (AWG17~AWG39)

Stator ID:15~65mm

Core length:7-110mm

Turns No.0-99999

Operation option: stepping/Auto

Stator poles: 6 poles, 9 poles, 12 poles,18 poles (Customized)

Air pressure:5~7kg/square centi-meter

Power:2KW, AC220V 50/60Hz

Weight: about 450kgs

Dimension: 1600(L)x1100(W)x1400(H)mm

The automatic brushless stator winding machine series WIND-TSM is suitable for the winding of various

types of brushless motor coils. The enameled wire is directly wound on the coil core. Compared with the

traditional method of stator coil winding and windings embedding method, it saves the cost of the

enameled wire and increases the number of coils (related to electric motor slot filling rate).

The magnetic flux increases the power of the motor. This machine WIND-TSM series can automatically

complete the winding, indexing, arraying, cutting and other processes. The operator only needs to take

the work of picking and placing the stator, which reduces the labor intensity of the operator and achieves

automation. In addition, the machine has a significant functional feature. The copper wire nozzles are

moving according to the setting parameter, so that the wound wire package is compact, neat and nice

looking.

| Parts list WIND-3A-TSM | |||

| Parts | Name | Spec. | Q'ty |

| 1 | Spindle belt | HTD8M-776 | 1pc |

| 2 | Arraying belt | HTD8M-624 | 1pc |

| 3 | Belt | HTD5M-825 | 1pc |

| 4 | Fuse | RT18-32 2A | 2pcs |

| 5 | Fuse | RT18-32 10A | 2pcs |

| 6 | Magnetic switch | AL-11RL-02 | 1pc |

| 8 | Ceramic wheel | ∮4 | 1pc |

| Tools: | |||

| 1 | Allen wrench | 8pcs | 1Set |

| 2 | Open end wrench | 13-16mm | 1pc |

| 3 | Word screwdriver | 4inches | 1pc |

| 4 | Phillips screwdriver | 4inches | 1pc |

| 5 | Wrench | 8pcs | 1Set |

| 6 | Tool box | 1pc | |

| 7 | Diagonal pliers | 1pc | |

| Custom part | |||

| 1 | Nozzle | 1pc | |

Please click below picture to view video

Contact Person: Ms. Emily

-

How to produce BLDC Motor Straight Lamination Stator Stack with Needle Winding Machine

-

12 Slots Needle Winding Machine BLDC Motor Stator 1.13mm AWG17 Copper Wire

-

Three Slots Vacuum Cleaner Motor Stator Needle Winding Inslot BLDC Winder

-

12 Slots Needle Winding Machine BLDC Motor Stator 1.13mm AWG17 Copper Wire

-

BLDC, PMSM and EV Motors Stator Needle Winding Machine For Straight Lamination Stator

-

BLDC Motor Stator Needle Winding Machine 60RPM Parallel Wires To 600RPM Thin Wire