|

|

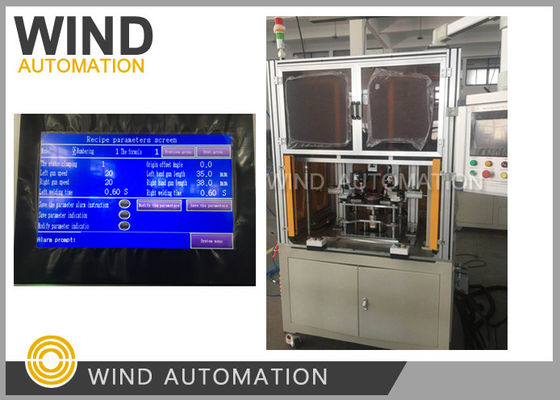

OEM Conductor Hot Staking Machine TIG Welding Fusion Machine

|

Product Details:

Payment & Shipping Terms:

|

| Welding Application: | Integrated Starter Generator Assembly | Automotive Technology: | Stator Silver Joint Tig Welding Application |

|---|---|---|---|

| Production Process: | The Stator Winding Process Involves Pin Forming, Insertion, Slot Insulation, Conductor Twisting ( Double Layer ), Conductor Ends TIG Welding, Star Joint TIG Welding Etc. | Welding Place: | Copper Conductor TIG Welding Machine |

| Fusing Type: | The Welding Operation And Setting Is Easy For Operator | PLC: | Mitsubishi |

| Gross Weight: | 600KGS Including Package Pallet | 4 Axis Servo Device: | Welding Spindle,Indexing Spindle, Feeding Shaft And Lifing Shaft With Mitsubishi Servo Motor |

| Highlight: | OEM conductor hot staking machine,TIG welding fusion machine,hot staking machine with warranty |

||

Integrated Starter Generator Conductor TIG Welding Fusion Machine

(1) Application:

Integrated Starter Generator assembly for 2 layers, 4 layer, 6 layers conductor end joint

(2)TIG Welding machine Advantages:

1. Related pure electrical car widely use TIG welding method

2. TIG welding is a kind of melting welding which have stronger connection of copper wire and copper wire,

3. Welding contacting resistance of TIG welding is smaller than resistance welding

(3) TIG Welding machine Q&A:

Question:

What is the setting reference of Stator Conductor TIG Welding machine?

Answer:

All the commissioning parmater are real-time data, below is our commissiong paramter data range for your reference,

Welding current: 90~120A

Welding time: 072s

Argon purity 99.999

Gas pressure < 1MPa

Gas flow rate 10 LPM

Weld torch 1.5mm away from the workpiece

(4) TIG Welding fusing machine Parameter:

Welding joint can be set, the starting joint can be set, and stand alone for welding amending can be set

Power Supply: 220V or 380V,50Hz

Welding spindle,Indexing spindle, Feeding shaft and Lifing shaft with Mitsubishi servo motor

PLC: Mitsubish 5U series

Touch screen: WEINVEIW

Cylinder: Airtac

Pressure:>0.5MPa

Weight: around 600KGS

Dimenstion:800*800*1500mm

Please click below photo to view video

Contact Person: Ms. Emily

-

220V / 380V 50Hz Commutator Fusing Machine With Touch Screen 600KGS

-

Tig Welding No Commutator Hot Staking Machine For Integrated Starter Generator Assembly

-

70KVA Brazing Armature Colector Spot Welding Hot Stacking Machine Welder

-

Automatic Hot Staking Machine Argon Arc Welding Machine To Weld Motor

-

Wire Soldering Commutator Fusing Machine Ultrasonic Wave Metal Welding For Car Stator

-

Fully Automatic Commutator Bar Hot Staking Machine For Small DC Brushed Motor