|

|

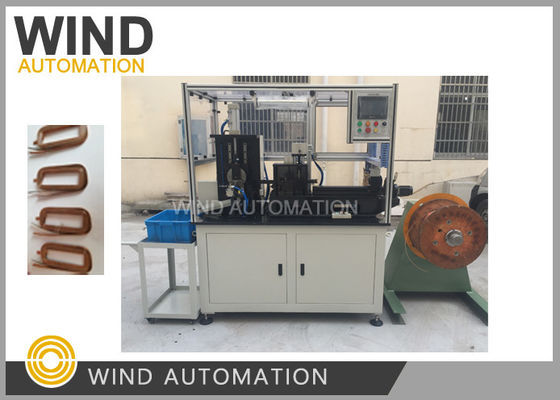

Automatic Field Coil Winder WIND-PCW-F3

|

Product Details:

|

| Condition: | New | Field Coil Winding: | Wire Feeding, Wire Straighten, Bend Star,wire Feeding,bending, |

|---|---|---|---|

| Winding Efficiency: | 15 To 30s' Per Piece, 2000pcs Per 8hours | Rotation: | Servo Motor Delta Or Simens |

| Controller: | PLC | HMI: | Screen Can Set Parameter |

| Highlight: | automatic coil winding machine,field coil winder WIND-PCW-F3,industrial coil winding equipment |

||

Fully Automatic Field coil winding machine WIND-PCW-F3

Machine working process

The machine can automatically wind the field coil with below process continuously,

Automatic wire feeding→ wire straightener → bend starting terminal→ wire feeding I, →bending→ wire feeding II→ press wire to tooling→ forming→ paper feeding and twisting winding→Wire cutting→ paper cutting→ twisting forming→unloading,

Output : around 15s’ to 30s’ per piece, around 2000pcs per shift/8hours

Machine Construction

1. Wire straighten mechanism,

Comprised of X,Y direction two set Guide wheel straightening

And cylinder, the cylinder pull wire to straighten it.

2. Wire feeding mechanism

Servo motor Delta drive the wire feeding module to feed the wire,

the wire feeding length can be setted on screen, and wire slotting limit can make sure

the wire trace is right

3. Starting terminal bending mechanism

Use cylinder to drive pulley to bend starting terminal,

The bending direction can be left or right

4. Wire bending mechanism

Comprised of press wire device and bending device,

bending direction can be left or right

- Cutting mechanism

With special Cutter dedicated for field coil

- Coil winding and unloading mechanism

Coil winding mechanism comprise of press wire device driven by cylinder,

Rotation device driven by Delta servo motor with reducer’s transmission part,

Tooling, tooling clamp device, ejection device.

The wire feeding mechanism feed the bended wire to fixed position of tooling,

press wire device begin to press the wire, rotation device rotate,

when rotate to setted position the paper will feeded ,

and continue to rotate to setted position, and cut paper, rotate to wind the coil.

The tooling clamping device loose, finshed coil come out and repeated from beginning.

7. Paper guide device

Comprised of paper rack, paper feeding motor and paper press device

8. The machine frame is Aluminum with organic glass

Simens or Delta PLC

Delta servo motor

Weinveiw touch screen

Weight: about 650KgMachine dimension: 1,500mm x 900 mm x 1700mm3

Contact Person: Ms. Emily

-

Single Station Field Magnetic Coil Winding Machine Conductor Coil Forming

-

1.8mm AWG13 Big Copper Wire Coil Winding Machine For Brushless Motor Stator

-

Linear Winding Line 600RPM Straight Lamination For BLDC PMSM And EV Motors

-

Commutator Armature Coil Winding Machine For Vacuum Cleaners Hammers Power Tool Motor

-

Round Wire Forming Machine 4.5KW Automotive Oil Pump Motor Rotor Armature

-

Car Generator Stator Wave Winding Coil And Wedge Inserter Machine For Alternator