|

|

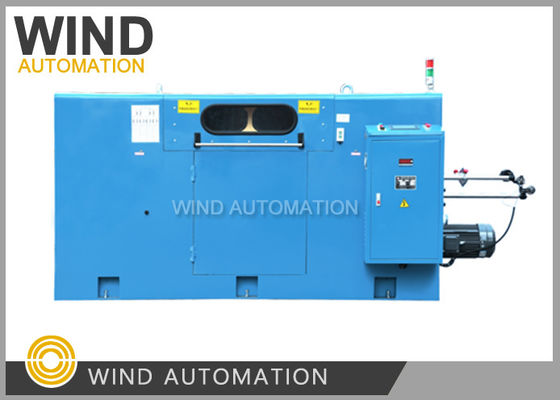

Power Cable / Copper Wire Twisting Machine 1600rpm For Bunch Strand Litz Wire

|

Product Details:

Payment & Shipping Terms:

|

| Litz Wire Type: | Copper Wire Or Aluminum Wire With Copper Enamel,CCA | Special Winding: | Wind Thin Wire Together And Twist |

|---|---|---|---|

| Wire Gauge: | F0.16~1.0mm Copper, 0.7mm To 3.0mm PVC Or Custom Made | Stranding Section Area: | F0.40mm ~ F6.0(mm2)/Copper |

| Take-up Bobbin: | F630mm | Stranding Direction: | Optional For Right Or Left |

| Driving Motor: | 10HP AC Motor With Controlled Inverter | After Sales: | Engineers Available To Service Machinery Overseas |

| Highlight: | stator coil winding machine,automatic coil winding machine |

||

1600RPM Copper Wire Power Cable Twisting Machine Produce Bunch Strand Litz Wire WIND-650P

Application:

Twisting power cable, telephone cable, electrical cable, computer cable, network cable, PVC cable etc.

The machine twist several wires or cables together to form slim and tight compressed wire,

which can produce litz wire of induction cookertop, rice cooker coils and current lead of electric wire,

cable cord, electrical line, power lines.

Advantages:

1. The winding spindle is critical part for winding quality which is taken special heat treatment

2. Magnetic tension device control the placement of wire safely to reels

3. In long time usage, 5year, 10 year later still very low noise during twisting

Parameter:

Wire diameter: f0.16~1.00 mm/Copper, f0.7~3.0mm/PVC

Max speed: 1600RPM (3200t/min)

Motor power: 10HP (7350W) AC Motor with controlled Inverter

Ball bearing:NSK FAG or KOYO

Voltage: three phase AC 380V 50/60 Hz

Weight: 2650KGS

Dimension: 3225(length)X1950(width)X1450(height)mm

The machine paint color can be custom made

Color per customer requirement (http://www.ralcolor.com/ )

![]()

Please click below picture to view video

Φ650 Double twist Bunching machine(Auto tension),

Manual tension control adjust tension manually inside the chamber with dry board abrading

Automatic tension control by a digital powder cluth tension controller, adjust the tension from the control

panel outside the chamber, it is convenient and precise than the manual mechanical device

In the short period of reform and opening up, the huge production capacity of China's cable manufacturing industry has made the world look impressive. In the world, the total output value of China's wire and cable has surpassed that of the United States, becoming the world's largest wire and cable producer. The sustained and rapid growth of China's economy has provided a huge market space for cable products. As China's power industry, data communication industry, urban rail transit industry, automobile industry and shipbuilding industries continue to expand, the demand for wire and cable is also It will grow rapidly, and conductor aluminum alloy technology and aluminum alloy cable products are also introduced in China. In the future, the wire and cable industry has huge potential for development.

With the development of China's power industry, the requirements for supporting industries are also getting higher and higher. Wire and cable equipment is an important part of the power supporting industry, and it is no exception. It faces the need for upgrading and adapting to China's power development. demand. Future wire and cable companies should work hard to improve technology, save raw materials, and develop new environmentally friendly materials.

However, China's wire and cable industry has long been hampered by the ills of some industries, and it is difficult to grow and develop. The output value of China's cable industry exceeds 1.2 trillion yuan, but the scale of enterprises is small, and the largest output value is only about 10 billion yuan. The scale is small, the innovation ability is poor, and the products can only be madly beaten in the low-end field. The overall average profit rate of the industry is less than 5%. In China, the pure buyer market has caused cable companies to have bad debts and bad debts. From time to time, a triangle crisis has also erupted. Most companies struggle in the fierce market competition.

However, technological advances have brought an excellent opportunity for China's wire and cable industry, that is, a new type of cable conductor material technology that began in the United States in 2006, namely conductor aluminum alloy technology and aluminum alloy cable products. Two US companies were brought into the Chinese market. After that, the Chinese aluminum alloy cable market was gradually detonated. Forecast data shows that in the next few years, even if China's aluminum alloy cable use level only reaches the current international level (30%), it will quickly form a huge market of up to 300 billion yuan. Such a huge market has undoubtedly attracted the attention of many companies in the industry.

After the aluminum alloy cable entered China, it has not been able to open the market widely. One important reason is the actual performance. Although the aluminum alloy cable does not improve the conductivity of the pure aluminum cable, the bending, compression creep and corrosion resistance of the aluminum alloy cable Other physical and mechanical properties have been greatly improved. Compared with copper cables, aluminum alloy cables have unparalleled advantages in terms of weight, price and engineering installation. In other words, in the premise of the same electrical performance and better mechanical properties, aluminum alloy cables are more economical and have a wide range of applications.

In such a huge market, many wire and cable companies want to get involved, but the Chinese cable industry, which is mainly composed of small and medium-sized wire and cable companies, has not been able to fully expand this market. This is due to the high technical content of aluminum alloy cables and production equipment. Large investment requires mature materials formula, production technology and talents. No matter whether it is a large enterprise or a small enterprise, this condition is not available for the time being. The production of conductive aluminum alloy materials requires a patented formula, which requires self-melting and casting to ensure the quality of the alloy material. Cable production also requires multiple production processes such as toughening, special technology, mature technology, specialized production and management personnel, special production equipment, etc., to produce qualified alloy cable products.

Contact Person: Ms. Emily

-

Single Station Field Magnetic Coil Winding Machine Conductor Coil Forming

-

1.8mm AWG13 Big Copper Wire Coil Winding Machine For Brushless Motor Stator

-

Linear Winding Line 600RPM Straight Lamination For BLDC PMSM And EV Motors

-

Commutator Armature Coil Winding Machine For Vacuum Cleaners Hammers Power Tool Motor

-

Round Wire Forming Machine 4.5KW Automotive Oil Pump Motor Rotor Armature

-

Car Generator Stator Wave Winding Coil And Wedge Inserter Machine For Alternator