|

|

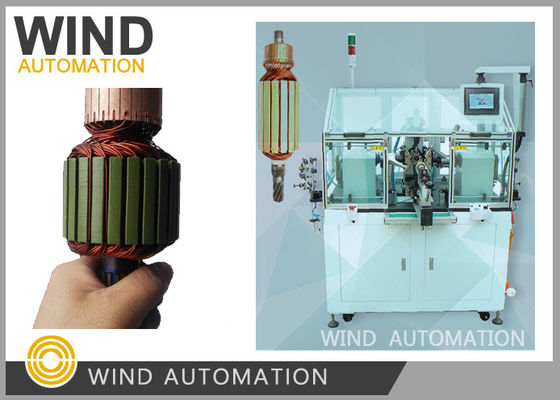

Armature Winder Rotor Winding Machine Two Flier Slotted Commutator PMDC Motor

|

Product Details:

Payment & Shipping Terms:

|

| Armature Type: | Slotted Type Riser Type Not Hook Type | ||

|---|---|---|---|

| Highlight: | armature coil winding machine,dynamic balancing machine |

||

Two Flier Slotted Commutator PMDC Motor Armature Winder Rotor Winding Machine

Application:

Armature winder for slotted type commutator armature,Vacuum cleaners hammers power tool

Hook/Tang type armature is easy to do armature winding, while armature with slotted type requires more complicated winding technology,

Why motor manufactuer use slotted commutator?

A slotted commutator motor could use less copper materials and run longer than a tang type commutator motor

Advantages:

1. Slot type armature with thin, thick wire machine can bed handled by automatic winding machine,

Machine had good feedback of winding a small 0.25mm wire diameter armature

2. Have good adaption for slot type commutator with groove,

No need to work with special designated slotting undercutting machine

3. Got good feedback in wide application from customers

4. 98% yield rate above assured when the slot commutator quality is good

5. Till now it is the best machine in China for winding slotted type armature

Feature:

|

Lap winding with double flyer wire

gauge range |

Usually 0.20~1.2mm, Max wire machine handled 1.35mm

(about AWG16)

|

|

Armature commutator type |

Slotted type riser type not hook type

|

|

Automatic or semi automatic |

You only need to load and unload armature, other actions such as

hooking, winding, indexing and cutting are wound by machine

automatcially

|

Winding and welding are the two most improtant process in building motors, WIND-ST-TD2B winding

machine is mainly for automatical lap winding a slotted type commutator armature as below

Wound slotted commutator Straight stack armature and Skew lamiantion rotor by armature winder![]()

Question and Answer:

Q:Wire size and Wire slot size relation (Length,width and depth)?

A: The wire slot should have enough space for the wire to stay inside Wire size 17AWG (1.15 mm),

Slot: blade width 1.143, length=7.14 mm, depth= 5.95 mm

and we think if the depth is bigger, the wire can acquire more space to stay inside slot,

while depth is more, length is more too,

Q: How to settle if there is indexing issue?

A: Could you please check if the commutator was pressed consistanctly each time at same

location according armature stack?

The push pin witness marks on the commutator are consistent.

Because armature commutator and stack position is very important for indexing consistantly

How to do pin hole test for the wound armature to verify the wound armature quality?

Operation steps for brine pinhole test for enamelled wire.

1.Prepare copper wire or wound armature samples according to the requirements

2. Connect the power supply, switch on the power, adjusting DC voltage meter adjustment knob,

the voltage value is 12V.

3. Copper wire or wound sample was immersed in 0.2% of the concentration of salt solution

(main ingredients are water, salt, pure alcohol 3%)

In the sample, the negative electrode connected with DC power supply, DC power connected with the

positive solution.

4.Within a minute, observe the change of the sample, if the sample has no obvious change, indicating

that the sample without pinhole, if the red and the penetrating phenomenon around the sample you

need to pay attention to, at this time, explain the pinhole, carefully count, there is the phenomenon of a

few, there are a few pinholes.

5.After the experiment, turn off the power and take out the sample

Please click below picture to view video

Contact Person: Ms. Emily

-

5Slot Armature Rotor Winding Machine DC Brush Motor Four Station WIND-ODD-1

-

Solar Energy Armature Coil Winding Machine Motor Winder 16 Hook 16 Slot

-

Solar Steering Motor Armature Winding Machine Flyer Winder Rotor Lap Winder

-

Automatic Dynamic Balancing Machine For Small Armature Rotor Adding Weight Type

-

CE Armature Winding Machine Dc Commutator Motor Fully Automatic Production Line

-

Flier Type Armature Winding Machine Fully Automatic 4 Pole Lap Coil Winder